Solid Sorbents:

A Step Change for the Carbon Capture Industry

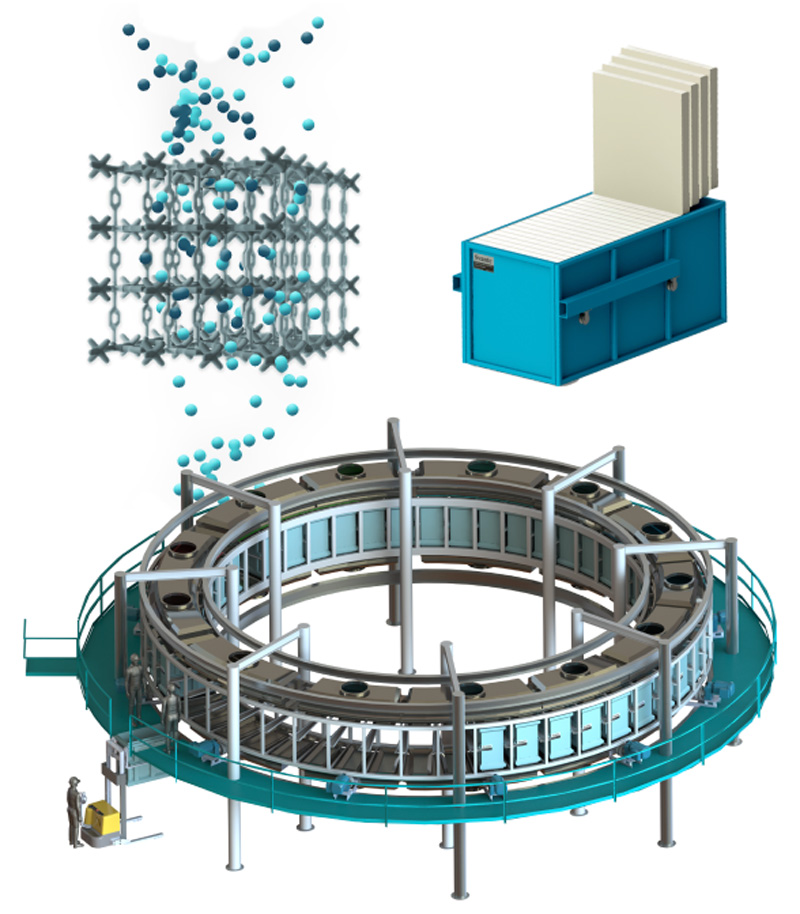

We are the leader in solid sorbent development, particularly metal-organic frameworks (MOFs) for carbon capture and removal. We use CALF-20 because of its energy efficiency, resistance to degradation in the face of post-combustion flue gas impurities, environmentally friendly profile, and low cost of ownership.

How Our Solid Sorbent Carbon Capture Technology Works

When you choose Svante’s solid sorbent-based filter technology for your carbon capture and removal project, you choose a complete technology package that is environmentally responsible, efficient, and tailored to your unique requirements.

Svante Carbon Capture Technology at its Core

The core of our technology is solid sorbents coated onto structured adsorbent filters, which are inserted into a contactor (carbon capture machine). The machine employs a patented rapid temperature swing adsorption process that captures and releases high purity CO2 from post-combustion flue gas streams every 60 seconds. Watch the video to visualize these steps.

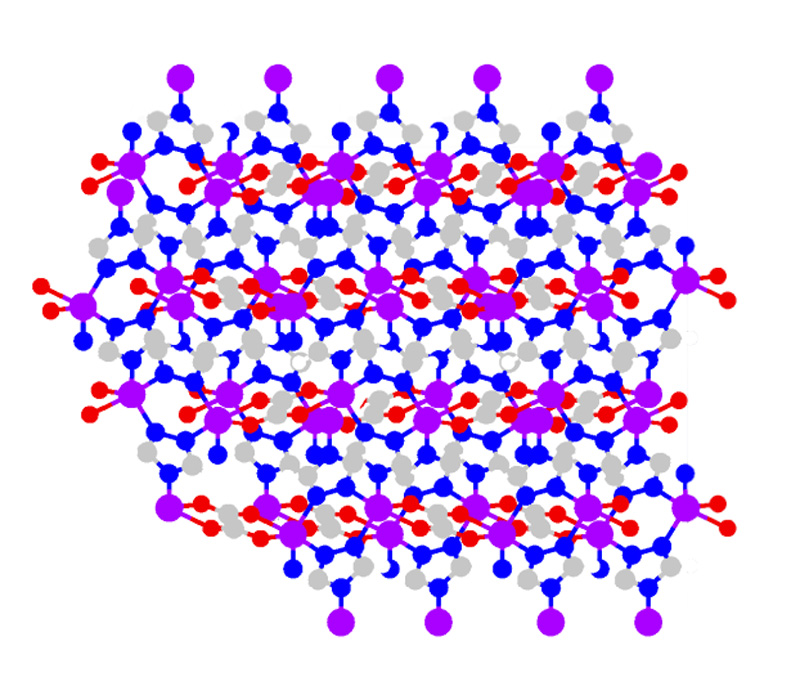

Under the Hood: CALF-20, Svante’s Award-Winning MOF for Carbon Capture

The solid sorbent we use for decarbonizing biogenic, industrial, and energy industries is called CALF-20. It’s a renowned metal-organic framework (MOF) that has several advantages for post-combustion carbon capture, including:

Environmentally responsible – with no toxic secondary emissions and inherent reusability

Our exhaustive tests show our metal organic framework technology doesn’t let off aerosol emissions or toxic chemical byproducts.

Resistant to SOx , NOx , O2 & H2O in flue gas

Unique resistance to SOx, NOx, oxygen, and moisture swing. It’s resistant to chemical degradation, which means simpler flue gas pretreatment design, less of a headache for operators and longer product lifetime.

High selectively for CO2 over water

Our solid sorbent materials are proven to selectively capture carbon molecules over H2O and other molecules contained in flue gas.

Physical adsorption means high energy efficiency

Physical adsorption relies on waker bonds rather than chemical bonds, resulting in reduced energy requirements for carbon capture.

Proven & effective at separating CO2 from nitrogen

Proven and effective at separating CO2 from nitrogen contained in diluted flue gas from cement, lime, steel, aluminum, fertilizer, pulp & paper, oil & gas, and hydrogen plants.

High CO2 storage capacity means smaller inventory of adsorbent

Our tailormade solid sorbents have a high storage capacity for carbon dioxide. A sugar-cube sized quantity of our sorbent materials has the surface area of a football field.

Carbon Capture Technology Suited for Your Industry

Svante’s point-source carbon capture technology is ideal for biogenic, industrial and energy emitters looking to decarbonize their facilities.

Pulp & Paper

Cement & Lime

Steel

Hydrogen

Refineries

Waste-to-Energy

Need Help with Carbon Capture Project Development?

Svante Development offers end-to-end support for capture project development. From finding the right project partners such as EPCs and storage providers to funding applications and more, Svante Development Company offers end-to-end support.

Svante’s Solid Sorbent Filters for Direct Air Capture (DAC)

In addition to post-combustion carbon capture applications, our solid sorbent-based filters can be used to capture CO₂ from the ambient air, known as direct air capture or “DAC”.

Easy to Operate, Modular Carbon Capture with a Low Vertical Profile

Svante’s modular, easy-to-use contactor that house our filters is delivered to industrial sites, along with balance of plant equipment — no complicated hazardous material, or space-taking chemical plants required.

Connect with Us

Learn more about how Svante’s solid sorbent carbon capture technology can work for your facility. Contact us for a consultation with one of our technical team.