Meet the Svante Carbon Capture Ecosystem.

Carbon capture filters

“Structured adsorbent laminate beds” featuring solid sorbent technology

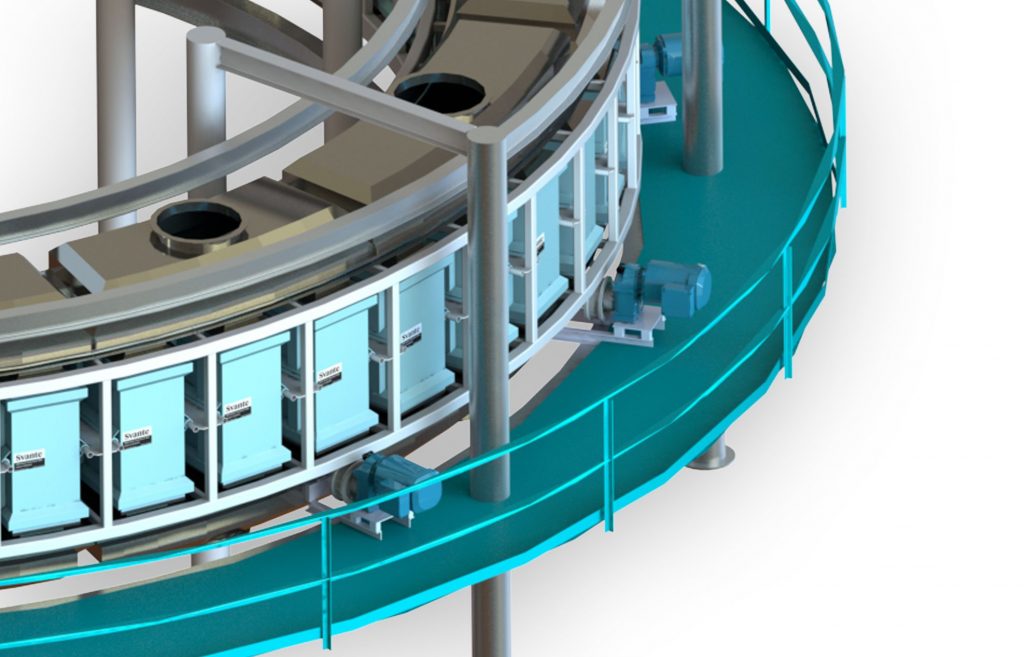

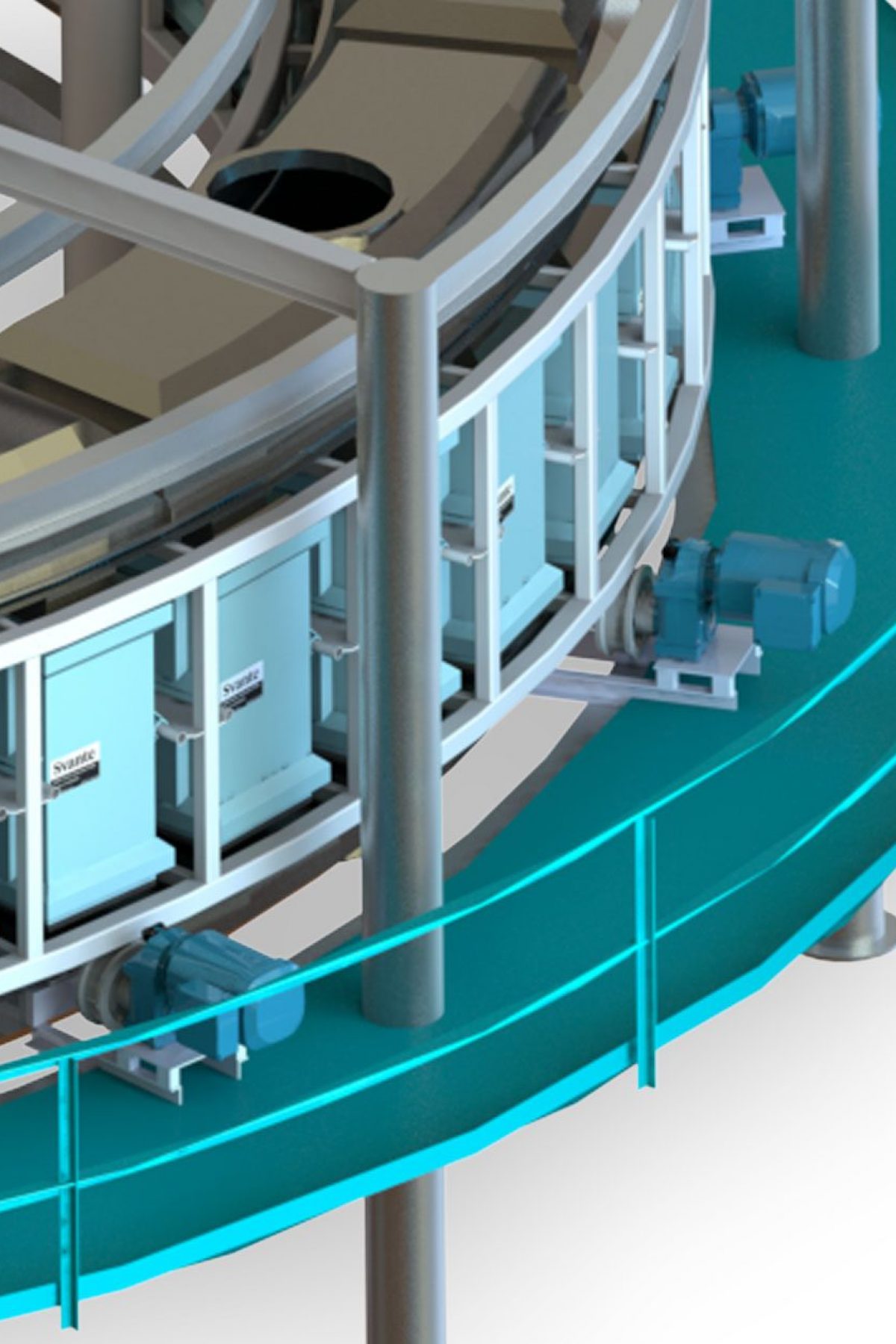

Rotary contactor machines

“RAMs” or “rotary adsorption machines”

Novel process design, VeloxoTherm™

Rapid cycle-temperature swing adsorption with direct steam regeneration

The Future of Commercial Carbon Capture Technology is Based on Solid Sorbents.

Solid sorbents, particularly metal-organic frameworks (MOFs), are a step change for the carbon capture industry. Their energy efficiency, resistance to degradation in the face of post-combustion flue gas impurities, and low cost of ownership make them ideal for carbon capture. That’s why our team of scientists and engineers elected to use them in the first place.

Our MOF captures CO2 from diluted flue gas streams with high capacity and selectivity over water. It captures 95% of the total CO2 emitted from industrial sources, adsorbing CO2 using direct low-pressure steam injection for regeneration.

Built for Industry. Backed by Science.

We’ve proven that MOFs are effective for industrial carbon capture. Our extensive research in this field has been published in the renowned Science Magazine, and we’ve been testing and optimizing our results in the lab and in the field for over 15 years.

MOFs are the Way Forward for Several Reasons.

✓ Reduced supply chain risk

We’ve partnered with BASF, the world’s largest chemical producer, to mitigate supply chain risk and scale-up the production of our MOF sorbent materials from lab to industrial scale. We’ve done this using a simple water-based process and green chemistry principles to minimize environmental impact.

✓ High CO2 storage capacity means smaller inventory of adsorbent

Our tailormade solid sorbents have a high storage capacity for carbon dioxide. A sugar-cube sized quantity of our sorbent materials has the surface area of a football field.

✓ Fast CO2 catch & release

The MOF sorbent material we use has a unique resistance to SOx, NOx, oxygen impurities, and moisture swing. It’s resistant to chemical degradation, which means less of a headache for operators and longer product lifetime.

Filters Made from Solid Sorbents Can be Applied to Direct Air Capture (DAC) & Point-Source Carbon Capture.

Our filters can be used for capturing CO2 from industrial flue gas – the source of the emission – which is called point-source carbon capture. They can also be used to capture CO2 from the air, known as direct air capture or “DAC”. Here’s how we make them:

01

Our patented, eco-friendly technology starts with nanomaterial sorbents called metal-organic frameworks or “MOFs” for point-source carbon capture, and porous amines for direct air capture.

02

The sorbent material gets mixed into a water-based slurry and is laid onto thin sheets of laminate, which are then cut and stacked.

03

The stacked laminate sheets become our nanoengineered filters, which we call “SABs” or structured adsorbent beds. These filters boast a high porosity and resistance to degradation.

Machinery That’s Compact, Easy to Use & Flexible Across Industry Applications.

Svante’s point-source technology can be applied to lime, aluminum, cement, steel, blue hydrogen, pulp & paper, oil & gas, fertilizer plants, and more.

Our modular carbon capture machines are delivered to industrial sites, along with key balance of plant equipment — no complicated hazardous material, or space-taking chemical plants required.

Machinery that’s compact, easy to use & flexible across industry applications.

Svante’s point-source technology can be applied to lime, aluminum, cement, steel, blue hydrogen, pulp & paper, oil & gas, fertilizer plants, and more.

Our modular carbon capture machines are delivered to industrial sites, along with key balance of plant equipment — no complicated hazardous material or space-taking chemical plants required.

How Svante’s Point-Source Carbon Capture Machines Work:

Step One

Step Two

Step Three

The compressed CO2 product can be moved into a pipeline where it can safely be transported and stored deep underground in saline aquifers or recycled and used for to make other products.

Minimize Your CO2 Footprint & Reach Your Emission Reduction Targets.

Contact our business development team to find out more about how our technology compares to other solutions, and how it can be applied to your business.