- Author: Claude Letourneau, President & CEO, Svante

Climate experts have long stressed the urgent need for global collaboration to combat humanity’s effect on climate change. This imperative for cooperation was palpable at COP28, the global climate summit I attended in Dubai this past December. As a first-time COP attendee, I was inspired by the pragmatic and substantive discussions, which included the business and financial sectors, and focused on accelerating efforts to limit global warming to 1.5 degrees Celsius.

The outcome was a strengthened commitment to bend the curve on greenhouse gas emissions by 2030, alongside the ongoing pathway to achieve net-zero emissions by 2050. Another notable aspect was the pledge to reduce unabated fossil fuels.

This is a big deal. It means that using fossil fuels will now require abating or diminishing the associated CO2 emissions. It marks a watershed moment in global climate action. However, these goals present urgent challenges, particularly for the industrial sector.

The vision of a green future means a world humming with the invisible flow of sustainably generated electrons that power our devices and light up our cities. But beneath this glow of energy lies a reality hidden in plain sight: the molecules of steel, concrete, glass, and plastic that make everything from phones to buildings arrive via industrial processes that send vast amounts of CO2 into the atmosphere. As the source of nearly one-quarter of global CO2 emissions, the industrial sector is increasingly pressed to identify and deploy solutions to cut those emissions.

Embracing a holistic approach

Many tout clean energy as the path forward. While vital, it’s only one piece of the puzzle. Clean energy as the sole solution neglects the industrial side of the equation, where CO2 emissions are a result not only of fossil fuels but of the fundamental chemistry that underlies many manufacturing processes. For example, every tonne of cement produced via the chemical reaction between limestone and other materials generates about one tonne of CO2.

A sustainable future demands a holistic approach. We must not only power our lives with clean electrons, but also ensure that the very atoms that build our world are obtained and processed responsibly. Only then can progress and environmental responsibility go hand in hand.

To achieve this, carbon capture and removal, use, and storage (CCUS) must be part of the solution. While not a cure-all, CCUS serves as an essential lever for decarbonizing sectors with hard-to-abate emissions. Though there has been uncertainty about how to effectively deploy these solutions, recent advancements and the launch of multiple new projects should inspire confidence in CCUS as an essential piece of the green industrial transition.

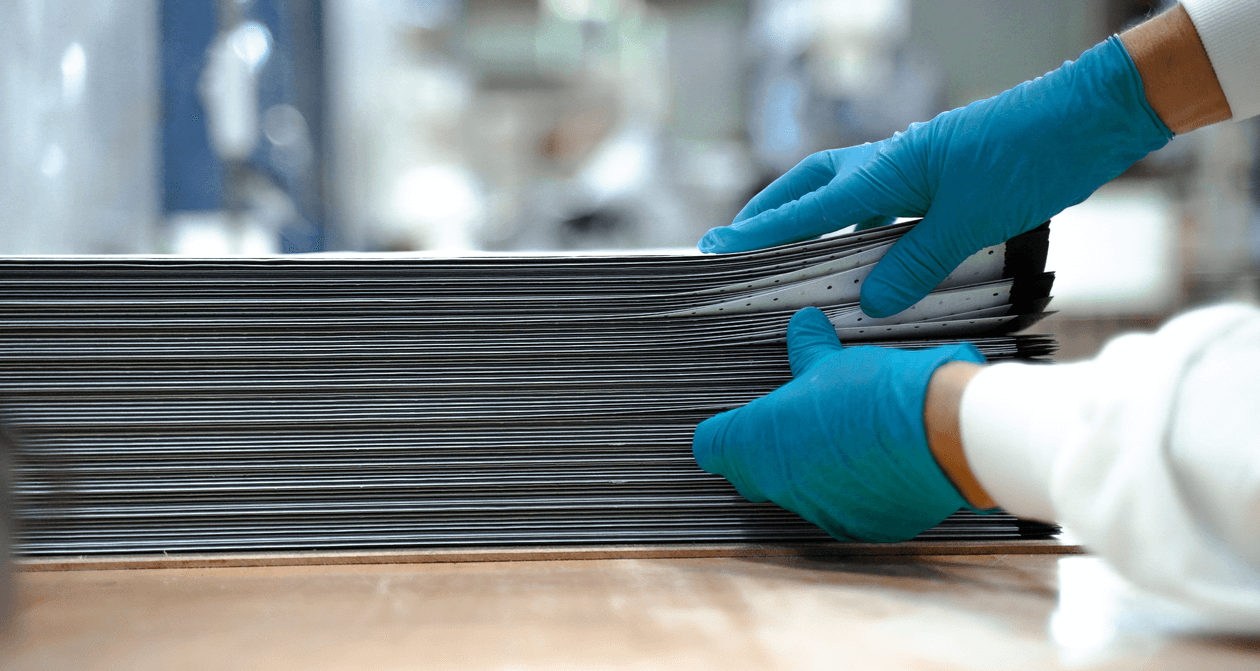

Indeed, significant progress has allowed leaders in the space to begin validating CCUS as an effective solution to making sustainable materials such as steel, cement, hydrogen, fertilizer, pulp and paper, and more.

There are three components of CCUS that make it especially suited for the green industrial transition: forward-looking technology, profit potential, and scalable deployment.

1. Forward-looking technology

Carbon capture and removal is often confused with other approaches like carbon sequestration or offsetting, which obscures the nuanced purpose and distinct attributes of each. Carbon capture and removal involves capturing the CO2 generated by biomass, industrial processes, or fossil fuels before it is released into the atmosphere. CCUS specifically is a set of technologies and processes that concentrate CO2 to 95% pipeline-grade purity so it can either be used to make other products in a closed loop or safely stored deep underground in saline aquifers.

New approaches to, and innovations in, CCUS illuminate its potential to drive progress. For example, Svante has developed a unique, commercial-scale CO2 filter technology based on solid nanomaterial sorbents, namely metal-organic frameworks (MOFs). MOFs provide unique advantages thanks to their inherent environmental sustainability, resistance to degradation, high adsorbent capacity, and low cost of ownership.

When included as part of a comprehensive climate strategy, the forward-looking technology at the heart of CCUS solutions will allow the industrial sector to accelerate its transition to a more sustainable future.

2. Profit potential

There is often a misconception that carbon capture and removal technology is prohibitively expensive. However, the expense of deploying CCUS technology pales in comparison to the potential costs and economic ramifications of unchecked climate change, such as damage to infrastructure, agriculture, and public health, among others.

Moreover, carbon emissions possess significant untapped value. The right solutions can transform CO2 from a waste product into a profitable asset. For instance, adding a carbon capture plant to an existing pulp and paper facility enables owners to tap into the voluntary carbon market to sell carbon credits as the facility shifts from “net neutral” to “net negative.”

Realizing these opportunities, however, hinges on overcoming regulatory hurdles, assessing market demand, and fostering cross-industry collaboration. Organizations must navigate these challenges adeptly and identify the solutions that allow them to maximize return on their investment (ROI). By demonstrating tangible ROI, carbon capture and removal solutions can help industrial businesses have a positive impact not only on the planet, but also on their bottom line.

3. Scalable deployment

Since the first COP in 1995, there has been ongoing debate about how to tackle climate change, with a polarized view of renewable energies versus fossil fuels. Now, there is a growing sense of urgency to deploy solutions at scale. This pressing need should propel innovation and collaboration.

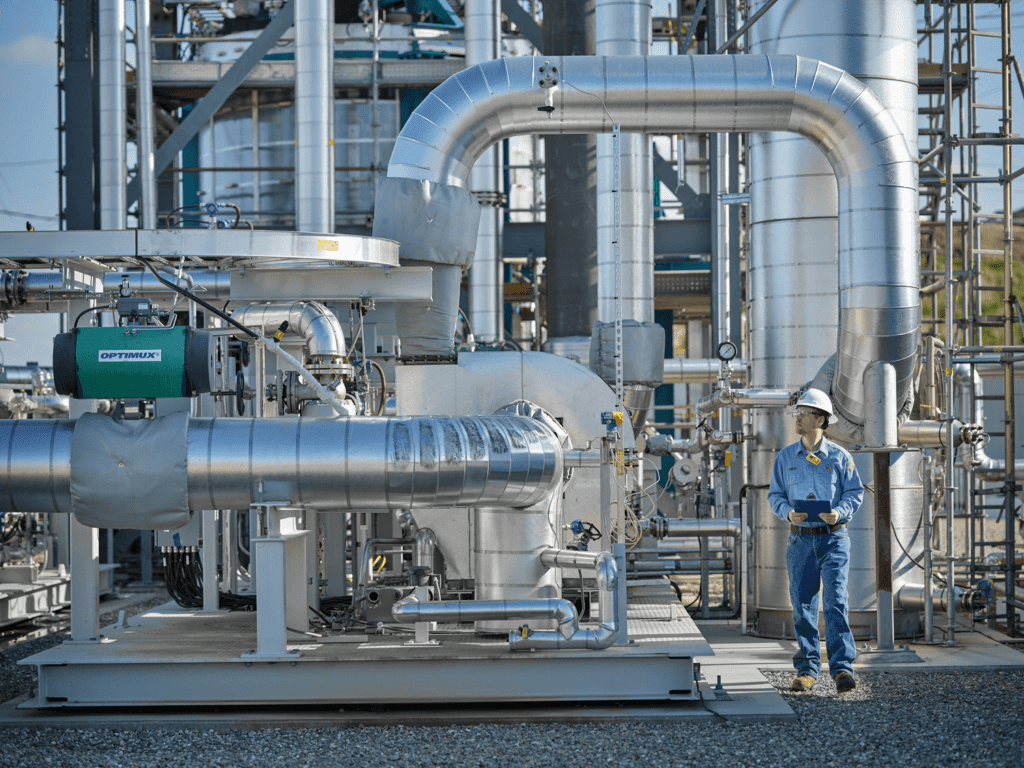

For instance, by partnering closely, Delek U.S. and Svante were chosen by the U.S. Department of Energy to negotiate a $95 million cost-sharing agreement to support a commercial carbon capture pilot project with the first-of-its-kind implementation of our innovative filter technology. It aims to capture 145,000 metric tonnes of CO2 annually, the equivalent of taking more than 32,000 gas-powered cars off the road every year.

Additionally, the Department of Energy selected Climeworks to develop three facilities that will pull CO2 directly out of the air, making the company eligible for more than $600 million in government funding. These direct air capture (DAC) hubs will be located in select states around the U.S. and will employ Svante’s filter technology.

As these and other projects get underway, strategic deployment will be critical. Svante’s integrated project delivery team brings together all stakeholders, providing a collaborative framework that facilitates efficient decision-making and accelerates implementation. The result? Projects are delivered on time and with cost certainty.

The new imperatives that emerged from COP28, combined with the increasing urgency around climate change, mean the industrial sector must develop a climate strategy that puts it on a swift trajectory to abate CO2 emissions. Central to that strategy should be CCUS. With advanced second-generation technology, a strong business model, and the ability to scale, these solutions offer promise for hard-to-abate sectors—and a means to catalyzing a more sustainable future.

Learn more about the possibilities of Svante’s carbon capture and removal technology.